Infrastructure

RAW MATERIAL STORAGE AREA

All type of raw material purchase from authorized mills as per quality standard required and delivery assured with quality test reports of every lot. The raw material received in our factory has been segregated and distinguish between wire rod & steel bar with tagging of lot number assigned for each order. Raw material of different grades placed in different section with colour coding & quality marks

COLD FORGING SECTION

In this section, we have capacity to make bolts from M6 to M20 by cold forging. With various requirement of Bolts with different heads, we have option to make them either on Bolt forming machine or Header machine. To perform this process, we have four bolt formers & six headers with various speeds according to diameter and length of bolt. We can make Hex Bolt, Carriage Bolt, Flange Bolt, T Bolts and any specialized bolt as per customer drawings. Our monthly capacity to produce bolts in this section is 100 MT.

HOT FORGING SECTION

In this section, we have capacity to make bolts from M22 to M56 by hot forging. We have two hot forge machines with induction power of 60W & 80W to make different types of bolts. We can make length upto 900mm for both full thread and half thread bolts. We can develop any specialized bolt as per customer drawing. We also have option for metal gathering to make different heads of bolts. Our plant have many lathe machines to perform cutting & facing of bolts before forging After forging, we do trimming of these bolts on press machine to get size of head of bolts as per drawing. Our monthly capacity to produce bolts in this section is 80 MT.

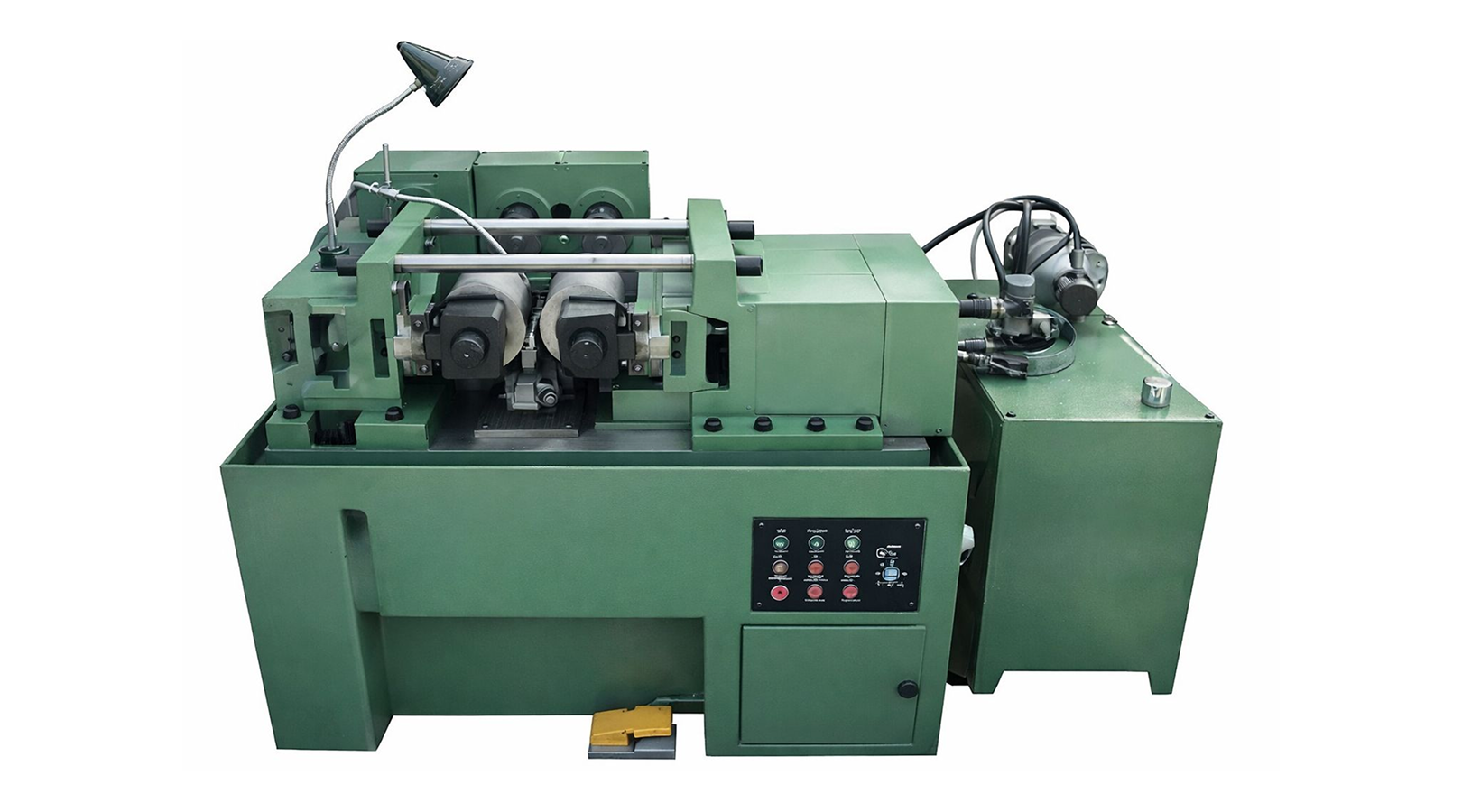

THREADING SECTION

For cold forged bolts we have different threading machines as per their size requirements. These machines can feed bolts for threading automatically or manually. Our plant can perform threading for full thread bolts & half thread bolts. The threading length is upto 105mm. For hot forged bolts we have several thread rolling machines upto 2 inch to perform threading on big bolts. These thread rolling machines can do threading on full thread as well as half thread bolts.

PRESS SECTION

We have more than 25 hydraulic & power press machines. The maximum capacity of our press machine is 200 MT. These press machines are capable to make the steel washers & U-bolts with various sizes. We have capacity to make washers upto 100 mm & thickness upto 10mm for various applications. We also make U-bolts in house as per different sizes required by customer. It is possible to make Stainless Steel washers & U-bolts in our premises.

HEAT TREATMENT PROCESS

There are different grades of steel in which we need to do heat treatment for bolts & nuts. After we get bolts from threading section we send them for heat treatment as per their steel grades requirements. For 8.8 grade bolts, we maintain HRC from 24-32. For 10.9 grade bolts, we maintain HRC from 34-38. For some bolts we have to do re-thread process after heat treatment to get different tolerance of threads. We have the facility to do heat treatment upto 300mm.

QUALITY CHECKS

Quality checks are very important at each and every step of hex bolt production. Starting from raw material we perform quality checks till final inspection of hex bolts. After heat treatment process, we have to check mechanical properties and hardness of every lot of hex bolts. On UTM machine, we check tensile strength, yield strength, elongation and surface reduction area. On Rockwell hardness tester, we regularly check the hardness of each lot of hex bolts. All type of chemical, mechanical and dimension requirement with tolerances are according to the steel grades.

FINISHING PLANT

For fasteners items, We have facilities for Zinc plating & Hot Dip Galvanization. Both plants are well equipped with quality machinery to get better finishes on all type of Bolts, Nut & Washers.

PACKING & DISPATCH

All items will be packed as per customer requirements and labels. The boxes made as per standard packing instructions & they can be easily load on Euro Pallet. We have in house container stuffing facility to check final dispatch of goods.